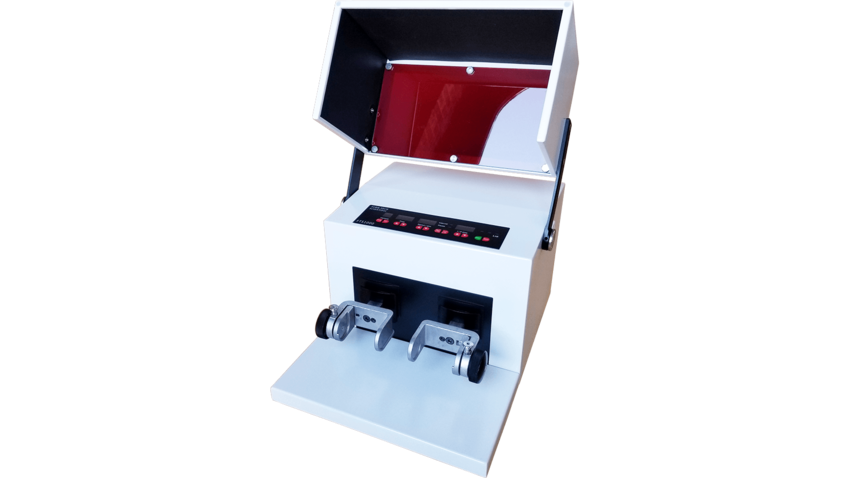

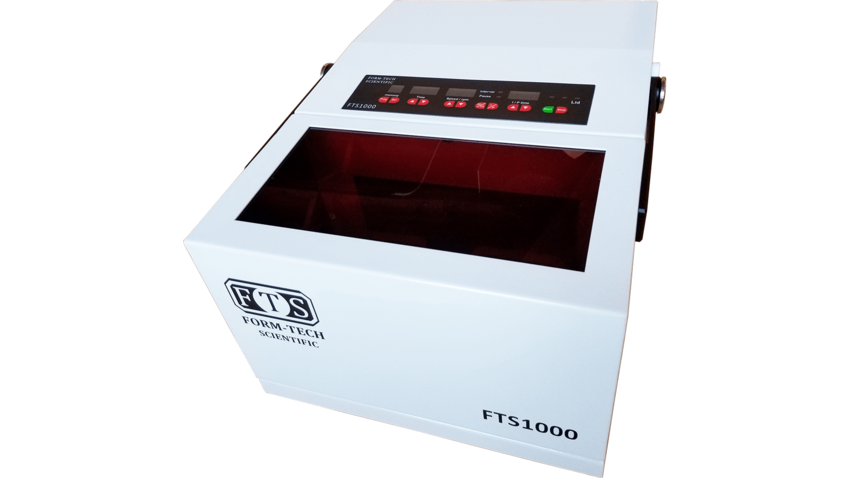

FTS-1000 Shaker Mill

Operating Principle

How it Works

The FTS-1000 grinds samples through a combination of impact and frictional forces. The grinding jars oscillate back and for at up to 1800 rpm(30 Hz), translating through a distance of approximately 25 mm. This causes the grinding balls to accelerate through the space inside the jar, resulting in high energy collisions between both each other and the inside walls of the jar. The sample is trapped between these surfaces and is pulverized. In addition to the high impact forces, frictional forces further contribute to the grinding and mixing of the sample. It is important to note that it is possible to affect the ratio of impact to frictional force by changing the number of grinding balls used. For high impact force and minimal friction, select a single large grinding ball. For high frictional force, select many small grinding balls.

Technical Specifications

Technical Specifications

| Grinding stations | 2 |

| Grinding speed | 180 - 1800 rpm (30 Hz) |

| Grinding time | 0:01 - 99:59 min |

| Storable grinding programs | 9 |

| Available jar sizes | 5, 15, 30 ml |

| Available jar materials | Stainless steel, PTFE, Zirconia |

| Tungsten carbide, PMMA | |

| Sample capacity | ≤ 12 ml x 2 |

| Sample feed size | ≤ 10 mm |

| Final particle size | ≥ 5 μm |

| Dimensions | 51 x 38 x 28 mm |

| Weight | ~ 34 kg |

| Power input | 110/220 V, 50/60 Hz |

| Rated power | 200 W |

Applications

Applications

The FTS-1000 ball mill is a versatile laboratory grinding/homogenizing instrument used in a wide range of industries with an even larger range of applications. Comminution of a bulk sample to a homogenous powder is often an important part of many industrial, quality control, research and development, and analytical methods. Bellow are listed some of these industries and applications.

Agriculture - Grinding corn, seeds, wheat, soil/fertilizer - This is often important in testing for pesticides and or other contaminants.

Electronics - Grinding circuit boards, resistors, transistors, diodes, and other semi conductors - This is often a sample preparation method for compliance testing such as ROHS, a European directive which restricts hazardous materials such as lead, hexavalent chromium, and many other substances in electronics.

Biological

- Grinding hair samples - For the detection of illegal drugs, pharmaceuticals, or banned substances in competitive sports.

- Grinding bone samples - Applicable in the area of forensics, archeology and others - Used to prepare samples for XRF (X-ray fluorescence), AES (atomic emission spectroscopy), and more.

- Tissue/cell samples - For homogenization and cell disruption/lysis - A fast and efficient method for the physical lysis of plant and animal cells to extract DNA/RNA.

Mechanochemistry

Mechanochemistry

Mechanochemistry is a solid state approach to chemical synthesis, which utilizes mechanical force as a means to conduct chemical reactions. Not only does this offer a greener approach to more traditional methods, which rely on toxic bulk solvents and high temperatures to induce chemical reactivity, but also provides accesses to chemical structures otherwise impossible to obtain through solution chemistry.

The FTS-1000 is a premium ball mill used in laboratories worldwide to conduct leading mechanochemical research. Whether you are interested in polymers, small organic compounds, metal organic frameworks (MOFs), in-situ techniques, or anything else, Form-Tech Scientific can offer you not only the best equipment, but decades of experience in mechanochemistry to support you in your groundbreaking research.

Overview

Designed with research in mind, the FTS-1000 is a compact bench-top laboratory ball mill ideal for milligram and gram scale grinding. The SmartSnap™ grinding jars utilize a patented closure system, making them easy to use and offering a hermetic leak proof seal for wet, dry, or air sensitive grinding. This machine provides an affordable yet versatile solution for small scale sample preparation and is especially well suited for Mechanochemistry.

________________________________________

Key Information

|

Available jar materials

|

✓Stainless steel ✓Zirconia |

✓PTFE ✓PMMA |

| Available jar sizes | ✓5 ml ✓15 ml ✓30 ml | |

| Typical grinding time* | < 1 min | |

| Sample capacity* | ≤ 12 ml x 2 | |

| Maximum grinding time | 99 min | |

| Sample feed size* | ≤ 10 mm | |

| Final particle size* | > 5 µm |

*Results are affected by and will vary depending on the physical properties of the material and machine parameters.

Accessories

Vendors

At Form-Tech Scientific, we work hard to provide our customers with the best products available on the market. Our products focus primarily on particle comminution but we understand that the needs of our customers in processing their samples sometimes go beyond this. That is why we carry not only our own products, but those of companies that represent innovation and quality in other areas of the sample preparation/processing field.