The FlackTek™ - Mixing & Degassing

About the Technology

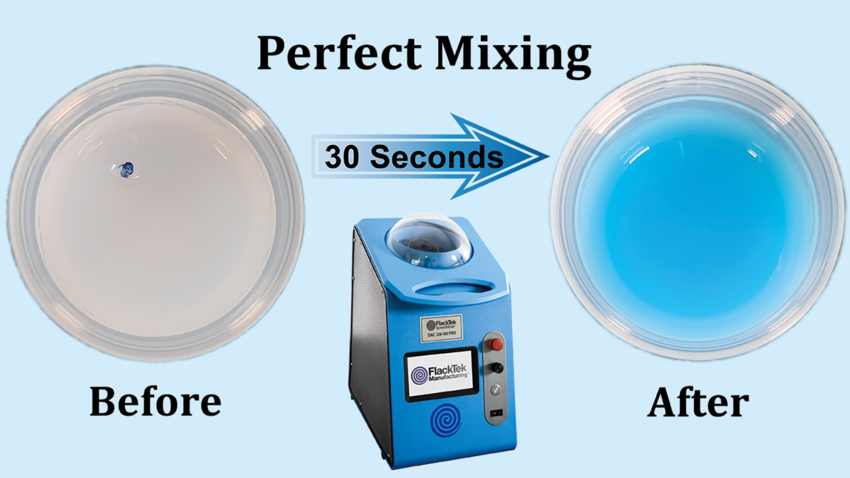

The mixing procedure of the FlackTek™ series is based on the double rotation of the mixing cup (hence the designation “Dual Asymmetric Centrifuge” or DAC). This combination of centrifugal forces acting on different levels enables very rapid mixing of the entire cup. The precision construction of the units gives the opposing forces an equilibrium with near zero vibration and low-noise operation.

Models & Technical Specifications

|

Laboratory Bench-Top Models |

||||

| Model (DAC) | 330-100 SE | 330-100 Pro | 515-200 SE | 515-200 Pro |

| Max Container Volume | 330 ml | 330 ml | 515 ml | 515 ml |

| Max Sample Weight (g) | 100 | 100 | 200 | 200 |

| Max Speed (rpm) | 3500 | 3500 | 2500 | 2500 |

| Self Balancing | Yes | Yes | Yes | Yes |

| Automatic Degassing | Yes | Yes | Yes | Yes |

| Vacuum Option | No | No | No | No |

| Touch Screen Inteface | Yes | Yes | Yes | Yes |

| Savable Programs | 3 | 150 | 3 | 150 |

| Dimensions HxWxD (in) | 21x12x16 | 21x12x16 | 21x12x16 | 21x12x16 |

| Weight (lb) | 75 | 75 | 75 | 75 |

| Power (V) | 120 | 120 | 120 | 120 |

Applications

Adhesives

- Polyurethanes – As polyurethane can encompass a large range of material qualities and attributes, the FlackTek™ is ideal for being versatile, repeatable, and fast! Industrial, pilot scale manufacturing and laboratory applications such as plastisols, gels and foams are all easily mixed. Use our vacuum FlackTek™ technology to remove moisture during mixing- no need to vacuum bake or strip the moisture prior to reacting/mixing! The FlackTek™ can perform vacuum or vacuumless mixing, depending upon your needs.

- Latex – Disperse your polymers and surfactants like never before. Glues, coatings, foams and additives applications are easily mixed with the FlackTek™. Formulate quicker by properly wetting out your additives and fillers under vacuum. We can handle both low and high viscosity mixing, and in a vacuum if needed.

- Epoxies – We have helped people mix countless epoxy and resin constituents, including bisphenols, novolac, aliphatic, and glycidylamines, and resins such as amines, anhydrides, phenols and thiols. Applications served include, adhesives, paints and coatings, electrical, composites, electronics, petro and petrochemical, marine and consumer, aerospace and bio and many more.

- Hot Melts – Need to formulate hot adhesives and polymers? We can handle a variety of viscosities and melt flow indexes. We’ve dealt with many EVA,TRP, PO, PA, PUR, SBC and TPU combinations, contact us to see how the FlackTek™ Dual Asymmetric Centrifuge can work for your application.

- Silicones – We have your polysiloxanes mastered. FlackTek™ machines have helped solve many mixing solutions for silicones in adhesives, as well as in sealants, lubricants, bio, electrical and thermal applications. Industries served include manufacturing, personal care products, medical, electronics, coatings, automotive, and many more!

Aerospace

- Coatings – Do you work with jet engine turbine coatings? We have experience with abradable coatings. Quickly and effectively mix your abradable material with no bubbles and a perfect mixture.

- C/C and RCC – Carbon fiber reinforced carbon and Carbon-Fiber-Reinforced Carbon? We have experience with C/C and RCC.

- Ceramics – Ceramic matrix composites and ceramic fiber reinforced ceramic? We have experience with CMCs and CFRC.

- Propellents – We can help you mix ammonium nitrates, ammonium perchlorate, potassium nitrates with aluminium, plasticizers, stabilizers, and/or burn rate modifiers.

- Microspheres – Monodisperse glass microspheres? We have experience mixing spacer-grade particles as well as other bondline control beads.

- Metamaterials – Metamaterial absorbers – we can mix them. We’ve dealt with solutions for photodetectors, solar and thermovoltaic applications.

- Fillers – Aliphatic, aromatic, and thermosetting polyimides – we can mix and disperse fillers and additives into them.

- Pre-Ceramics – Polysilazane, Lonsdaleite, allotropes of carbob, poly(hydridocarbyne), and ceramic matrix. We have mixing and formulating your pre-ceramics covered.

- Advanced or multi-materials – Radar transparent materials, acoustic attenuating materials, radome materials, dielectrics and buoyancy foams. We help you repeatably formulate and mix all your needed materials.

- Resins – Are you mixing Henkel, PPG, 3M, Cytec, Huntsman, BASF, EPO-TEK resins? From epoxy, to urethane to silicone to virtually every other resin / reactive chemistry, we can help you mix quicker, easier, and more repeatably…with no bubbles!

- CAB-O-SIL® or AEROSIL® – Adding CAB-O-SIL® or AEROSIL® into your formulation? The FlackTek™ can quickly mix, disperse and deair your formulation.

- Optics – Optical bonding- quickly mix and deair optically clear epoxy, silicone, urethanes, etc for a 100% bubble-free result every time!

- Filled Syringes – Do you need to use a syringe for your application? Contact us to find out more about our SpeeDisc technology to successfully transfer materials from a mixing cup into the syringe of your choice- with no bubbles or mess!

Frequently Asked Questions

Q: What is the thickest or highest viscosity material the FlackTek™ can handle?

A: We can mix anything including up to multi-million centipoise fluids.

Q: Will the FlackTek™ ‘over mix’ my materials?

A: No, our variable speed machine can be properly programmed to offer a truly optimized mix cycle unique to your specific materials.

Q: Is the onsite demonstration completely free?

A: Yes. We believe wholeheartedly in the FlackTek™ machines and are happy to demonstrate to any interested parties that have a mixing need. Completely free.

Q: Do I really have to see it to believe it?

A: Yes. Seeing our technology work for your application first hand is the best way to show yourself and others that we may offer the perfect solution or an answer to a problem you didn’t know you had.

Q: Is your technology scaleable?

A: Yes, thousands of the products that you see and use everyday have undergone the product cycle of formulation, R&D, pilot scale in the FlackTek™ and then scaled into production qualities using traditional mixing technologies. The FlackTek™ helps you formulate and find your desired material quicker and easier.

Q: Do you only have lab scale mixers?

A: Our line of FlackTek™ machines cover <1g to over 200kg and everywhere in between.

Q: Are your mixing containers disposable?

A: You can choose to reuse or dispose of our mixing containers. They are priced at disposable rate so that cleanup can be avoided. Some customers mix, store, and even sell material directly in our containers.

Q: How important is power when Mixing?

A: Power, or spin speed (RPM), is the basis of our mixing. Having adequate power is essential to ensuring a proper, repeatable, bubble free mixing of thick and thin materials.

Q: Does the FlackTek™ actually remove bubbles when mixing?

A: Yes. The motion of our mixing will remove macroscopic bubbles or voids from your materials in-situ during the mixing operation. If you would like to remove microscopic, adsorbed air, solvent, moisture or other contaminants from your material, our vacuum FlackTek may be the best solution. Contact us to compare vacuum vs non-vacuum FlackTek™ machines.

Q: Who will be visiting my facility for the demonstration?

A: Our team consist of local experts throughout the country with backgrounds ranging form chemistry, to material science to engineering- we will find the perfect fit for you. Each local FlackTek™ contact is fully trained and comes with a technical background. We have seen thousands of different problems throughout industry and are prepared with solutions for your specific mixing need.

Q: Does the FlackTek™ have any blades?

A: No! The FlackTek™ works on the principle of our original patent on the Dual asymmetric Centrifuge.

Overview

The FlackTek™ is the most advanced piece of laboratory equipment on the market for sample preparation and is capable of homogenizing, degassing, and grinding almost any sample. All FlackTeks are capable of both homogenization and grinding however, this page focusses on homogenization and degassing. For Grinding, click here.

The FlackTek™ eliminates air bubbles and can utilize either single use or reusable containers. It is used to mix colloids, fluids, powders, pastes, creams, grease, resins, inks, paints and silicone mixtures.

These lab size, small batch, manufacturing mixers have the capacity to mix samples in seconds. Sample sizes range from, 1g - 20Kg, and can be mixed in cups and cartridges, including Semco. Absolutely no cleanup required.

Key Features

Highly Reproducible Results – Perfect mixing every time thanks to precision centrifugal mixing.

No Bubbles – Mixing and degassing/deaeration are achieved simultaneously thanks to DAC (dual asymmetric centrifugal) technology.

No Cleanup – Mixing can be performed in inexpensive and disposable containers.

Quickly Mix Anything – Mix semi-solids, pastes, oils, liquids, powders, creams, in any combination, within a few seconds to a few minutes. High viscosity mixing is no challenge.

Virtually No Material Loss – No blades or bowls to clean. Another reason that centrifugal mixers are superior to bladed mixers.

Optional Vacuum – Removes submicron-level air, moisture, solvents, etc, caught in materials.

Syringe Packaging – Patented mixing directly in a syringe or easily transfer from mixing cup to syringes.

Accessories

Vendors

At Form-Tech Scientific, we work hard to provide our customers with the best products available on the market. Our products focus primarily on particle comminution but we understand that the needs of our customers in processing their samples sometimes go beyond this. That is why we carry not only our own products, but those of companies that represent innovation and quality in other areas of the sample preparation/processing field.