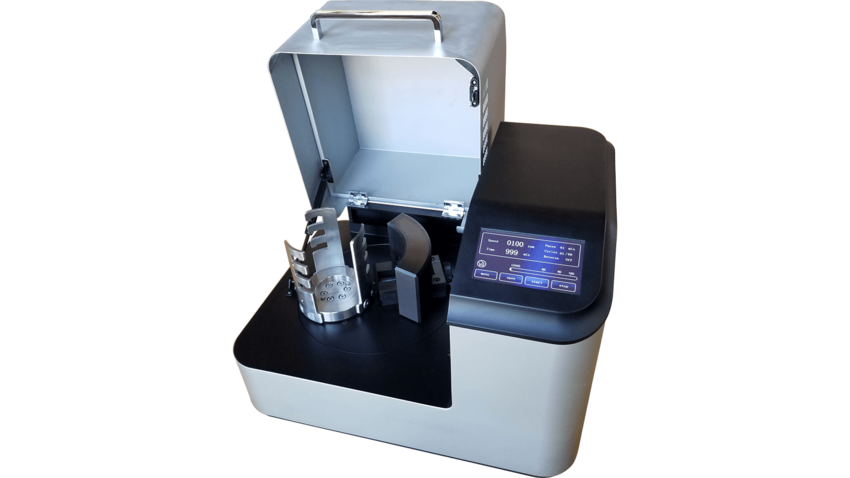

PR-1000 Planetary Mill

Operating Principle

How it Works

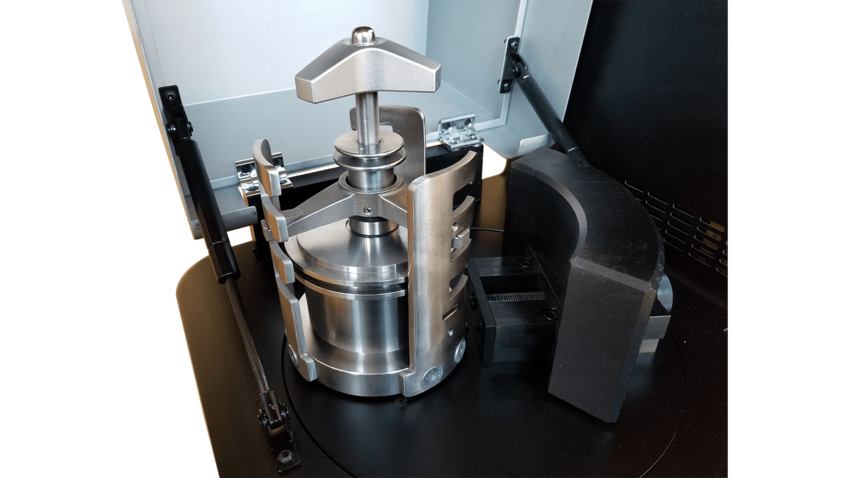

Planetary mills function by way of two super imposed, but counter rotational motions. What is referred to as the sun wheel (the flat disc upon which the grinding jar is located) rotates on it's center axis, while at the same time the grinding jar rotates on its own center axis in the opposite direction. This motion subjects the balls and sample inside the grinding jar to what are known as Coriolis forces. This causes the balls to first slide around the outside of the jar and then to accelerate across the jar to collide with the other side at high speed. This combination of impact and frictional forces leads to very small particle sizes in the nm range.

Technical Specifications

Technical Specifications

| Grinding stations | 1 |

| Grinding speed | 100 - 650 rpm |

| Grinding time | 1 - 999 min |

| Pause time | 1 - 99 min |

| Number of cycles | 1 - 99 |

| Storable grinding programs | 9 |

| Available jar sizes | 50, 125, 250, 500 ml |

| Available jar materials | Stainless steel, Agate, Zirconia |

| Tungsten carbide, Silicon nitride | |

| Sintered aluminum oxide (Alumina) | |

| Maximum sample capacity | < 230 ml |

| Sample feed size | < 11 mm |

| Final particle size | > 0.1 μm |

| Effective sun wheel diameter | 260 mm |

| Dimensions (W x D x H) | 685 x 510 x 506 mm |

| Weight | ~ 120 kg |

| Power input | 110/220 V, 50/60 Hz |

| Rated power | 750 W |

Overview

The PR-1000 Planetary Ball Mill is a single station medium scale instrument used for grinding dry, wet, and even oily materials. This machine features an updated modern and easy to clean design with a 7 inch touch display for quick and intuitive operation. An extended operating time and the ability to accommodate a wide rang of sample sizes (from tens to hundreds of grams) make the PR-1000 a versatile and capable instrument. This machine is ideal for sample comminution, mechanical alloying, colloidal grinding, and mechanochemistry/mechanical activation.

Key Information

|

Available jar materials

|

✓Stainless steel ✓Tungsten carbide |

✓Alumina ✓Agate |

✓Zirconia

|

|

| Available jar sizes | ✓50 ml | ✓125 ml | ||

| ✓250 ml | ✓500 ml | |||

| Sample capacity* | < 230 ml | |||

| Continuous grinding time | 1 - 999 min | |||

| Pause time | 1 - 99 min | |||

| Cycles | 1 - 99 | |||

| Sample feed size* | < 11 mm | |||

| Final particle size* | > 0.1 µm | |||

*Results are affected by and will vary depending on the physical properties of the material and machine parameters.

Vendors

At Form-Tech Scientific, we work hard to provide our customers with the best products available on the market. Our products focus primarily on particle comminution but we understand that the needs of our customers in processing their samples sometimes go beyond this. That is why we carry not only our own products, but those of companies that represent innovation and quality in other areas of the sample preparation/processing field.